On the face of it, thermal stratification is a process that is easily understood. But understanding how this process affects your company’s bottom line, and what can be done about it, is another matter altogether. Fortunately, it’s not as complicated as you might think!

This article will explain the process, as well as what can be done about it and how the solution will save you money in the long run.

What is Thermal Stratification?

Thermal stratification is the layering of different air temperatures from floor to ceiling, which results from the cycle of warm air rising to the ceiling and cold air falling to the floor. In large, indoor spaces, this dynamic can lead to huge disparities in temperature and humidity levels at different points.

In buildings with significant stratification, temperature differentials in excess of 1°C per vertical foot are common, and they can be even larger in buildings with very high ceilings. Although that might not sound like much to most people, it certainly feels like a lot to your building’s heating, ventilation, and air conditioning (HVAC) systems!

Costs and Effects

Although a difference in air temperatures at different points throughout an indoor space seems natural and normal, it could actually be costing your operation a lot of money. Especially for large warehouses and manufacturing facilities, thermal stratification can gobble up a huge amount of energy to correct through the heating (or cooling) of your workspace.

HVAC systems are designed to maintain a certain temperature. But thermostats are typically placed at floor level, which leads HVAC systems to overheat or overcool to compensate for thermal stratification. This problem is especially pronounced in cold climates as systems over deliver hot air as they try to reach the desired temperature setting, but it is also an issue to contend with when trying to cool large spaces in warmer conditions.

Solution

Since thermal stratification poses so many issues for large buildings, what can be done? As complicated as it might seem, there is a one-word answer to this problem: destratification.

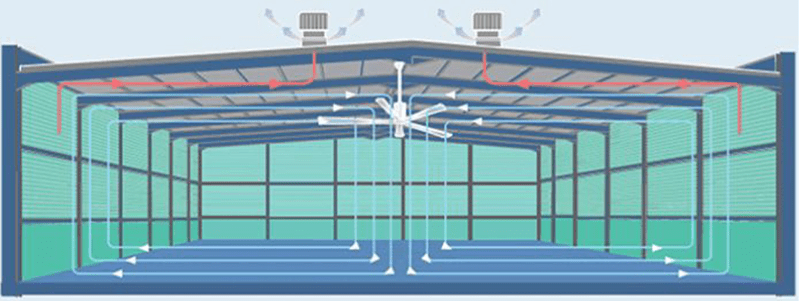

The process of diminishing thermal stratification is known as destratification. To achieve this result, the most cost-effective solutions are high-volume, low-speed (HVLS) fans.

HVLS fans are large ceiling fans with blades of at least seven feet in length that are particularly effective at destratifying the air in large spaces. As you gathered from the name, these fans operate at low speeds, which makes them highly efficient at moving large volumes of air and preventing thermal stratification.

It all seems a bit counter-intuitive because they are so large, but these devices require very little energy. Instead of whirling around at great speed, as you would normally see with a household ceiling fan, HVLS fans move slowly to avoid creating turbulence and air resistance, which is why they are so effective at promoting destratification.

The Benefits

By facilitating the destratification of hot and cold air in your workplace, HVLS fans provide immediate benefits in the short term and huge savings in the long run. Installing these fans in your workplace will help:

- Reduce costs – Heating and air conditioning require a lot of energy, which costs money. By reducing the load on your building’s HVAC systems, HVLS fans can be a source of huge savings.

- Increase productivity – Workers in a comfortable environment are more productive, as output and efficiency drop when employees are either too hot or too cold.

- Protect the environment – By reducing your companies energy needs, you are also reducing its carbon footprint.

Refresh Fans

As a leading provider of HVLS fans, Refresh Fans has the knowledge, expertise and products to help your company. Call toll free (1-866-450-3498) or click here to contact one of their experts for more information.