EQ HVLS fans offer a host of benefits that set them apart as an attractive option for various commercial and industrial applications. Let’s explore some of the significant advantages they bring:

- Reduced Energy Costs

One of the primary advantages of EQ HVLS fans lies in their ability to reduce cooling and heating expenses significantly. By utilizing only a fraction of the energy consumed by traditional HVAC systems, these fans can cut cooling costs by up to 50% and heating costs by up to 30%. This remarkable energy efficiency benefits the environment and contributes to substantial savings for businesses.

- Improved Air Circulation

EQ HVLS fans create a horizontal floor jet, effectively eliminating “dead” zones and preventing stagnant air pockets from forming. This superior air circulation enhances overall indoor air quality by preventing the buildup of moisture, dust, and other airborne pollutants. As a result, the environment becomes more pleasant and conducive to productivity.

- Reduced Humidity Levels

These high-volume, low-speed fans actively promote evaporation, leading to reduced humidity levels in the surroundings. By doing so, they effectively prevent the growth of mold and bacteria, which could otherwise compromise indoor air quality and lead to health issues. Employees and occupants benefit from a healthier and more comfortable atmosphere, improving well-being and morale.

- Enhanced Employee Productivity

Studies have shown that employees perform better when they are comfortable in their working environment. EQ HVLS fans can create a cooling effect of up to 10 degrees in warm conditions, providing relief during hot weather. This, in turn, contributes to higher employee morale and reduced absenteeism, further benefiting businesses in terms of productivity and overall performance.

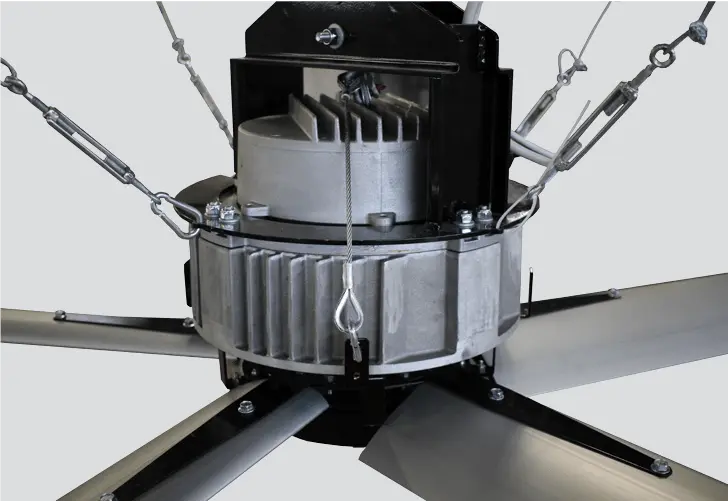

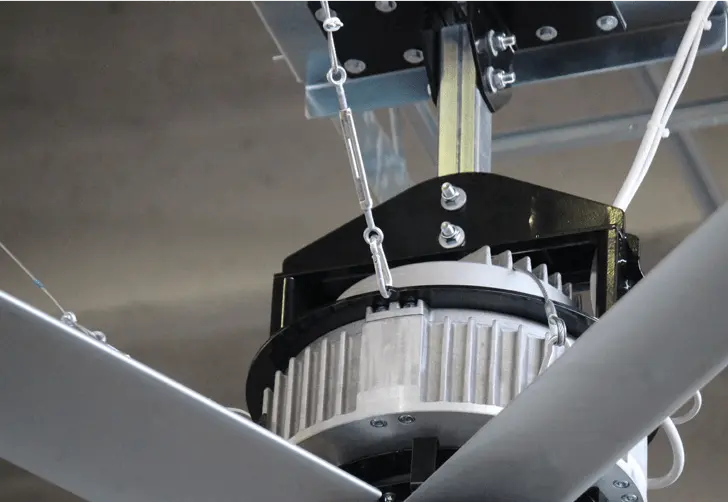

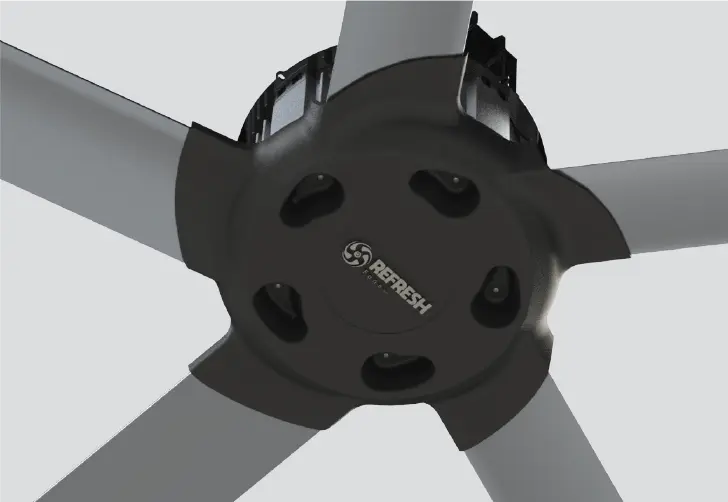

- Minimal Maintenance with Aesthetic Appeal

HVLS fans offer the dual benefit of requiring minimal maintenance and looking visually appealing. Compared to traditional fans, HVLS fans have fewer moving parts, which means they need less maintenance resulting in reduced maintenance costs. With a sleek and modern design, they can seamlessly blend into different spaces, enhancing the overall aesthetic.