Temperature management in a warehouse environment is frequently undervalued despite its critical role. A stable temperature significantly impacts workers’ comfort, product quality, energy efficiency, and overall operation expenses. If you aim to enhance your warehouse conditions and economize, keep reading. This article provides implementable steps for superior warehouse temperature regulation that could ultimately save substantial sums.

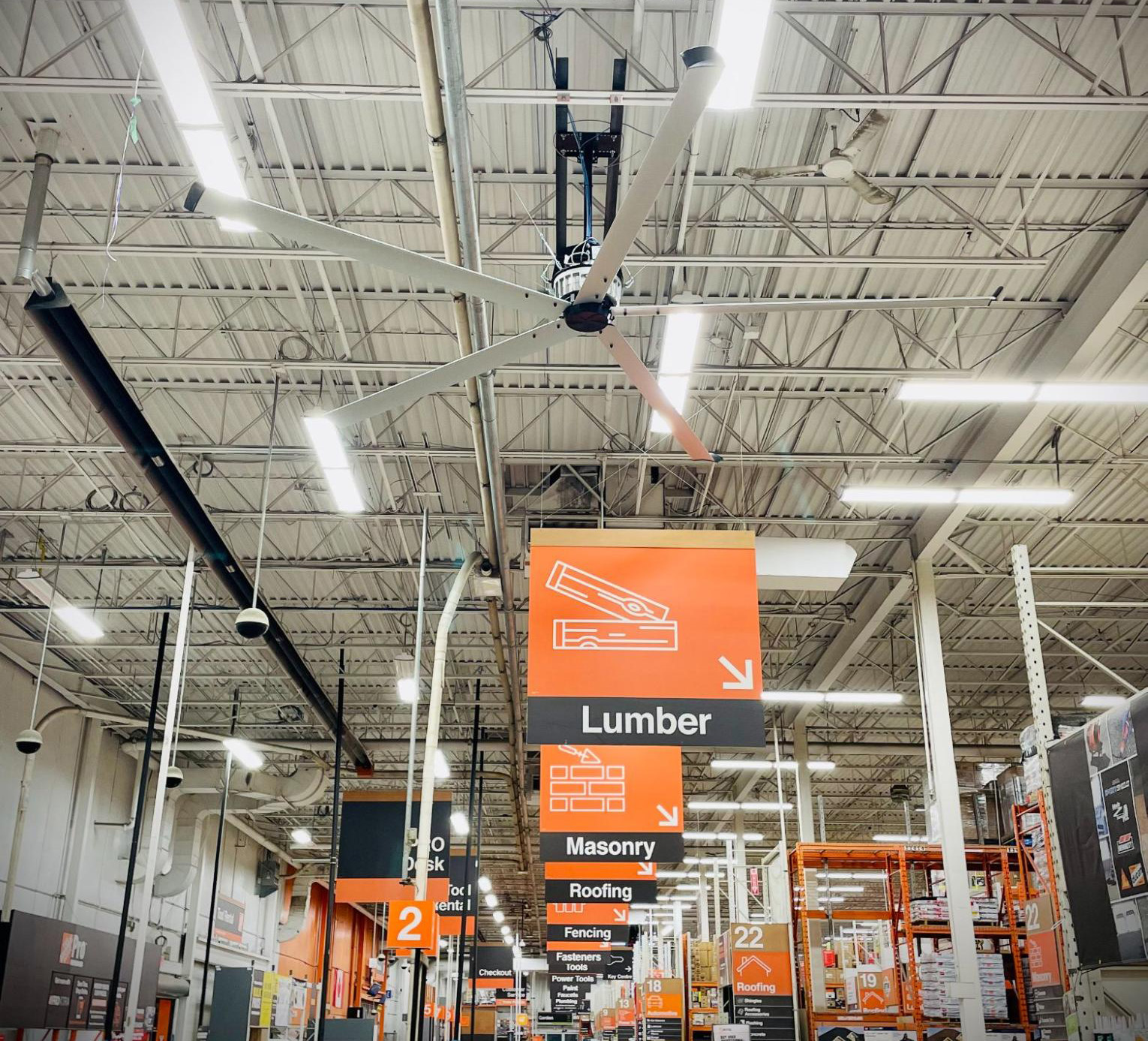

Bring in the Fans

High-quality, large industrial ceiling fans can drastically improve your warehouse’s temperature control. These heavy-duty appliances generate a continuous airflow, mitigating the build-up of heat and maintaining a consistently comfortable climate. Additionally, these fans enhance the efficiency of air conditioning systems by promoting optimal air circulation throughout the space. The steady distribution of cool air reduces the burden on your AC units, leading to less energy consumption. This, in turn, translates into noticeable reductions in your utility bills. Another overlooked benefit of employing industrial fans is their impact on your workforce’s productivity. A less stuffy, more agreeable working environment can increase employee comfort and morale, contributing to higher work output. Therefore, the benefits of incorporating industrial fans into your warehouse far outweigh the costs, making it an investment worth considering.

Having said this, integrating warehouse ceiling fans into your climate control strategy offers a comprehensive solution for maintaining optimal temperatures year-round. These heavy-duty fans not only excel in cooling during warmer seasons but also play a pivotal role in creating a comfortable environment during winter. By generating continuous airflow, these fans address both heat build-up and challenges posed by colder temperatures. During winter, these fans can be strategically set to operate in reverse, gently pushing accumulated warm air near the ceiling back down to the floor. This approach ensures a more consistent temperature throughout the warehouse, overcoming the natural tendency of warm air to rise. The versatility of industrial fans is evident in their ability to complement heating systems, working in tandem with HVAC or industrial heaters to distribute warm air evenly and prevent hotspots.

Analyzing the Current Situation

Before making any modifications to your warehouse, a thorough analysis of the existing temperature conditions and energy use is crucial. Delve deep into understanding your warehouse’s unique energy usage trends. Are there specific times of the day when your energy use surges? Do certain areas in your warehouse consistently run hotter than others? Gaining insight into these patterns is key to developing the most effective, tailored solutions for temperature control and maximizing energy efficiency. Make use of monitoring tools and sensors to gather accurate data. This analysis serves as the foundation for your warehouse improvement plan, guiding the choice of fans, insulation, HVAC systems, and ventilation methods best suited to your specific needs.

Insulate Your Warehouse Properly

Effective insulation is pivotal in achieving a suitable warehouse temperature. Appropriate insulating materials can prevent possible leaks, providing a shield against outdoor weather and resulting in superior internal temperature management. This ensures a comfortable workspace and decreases dependency on heating and cooling systems.

In warmer seasons, quality insulation aids in keeping the warehouse cool by restricting external heat. Conversely, in winter, it helps retain heat within the warehouse, resulting in a cozy atmosphere. The versatile nature of insulation can dramatically reduce dependence on energy-draining HVAC systems, particularly in regions with extreme weather fluctuations.

While good insulation might seem expensive initially, its cost-effectiveness becomes evident over time due to the significant energy savings it offers, leading to decreased utility bills. However, bear in mind that not all insulation materials are alike. Choosing the suitable type for your warehouse needs and local weather is crucial.

Using Energy-Efficient HVAC Systems

HVAC systems considerably impact the energy use of warehouses. Transitioning to efficient HVAC technologies can result in substantial cost reductions. These advanced systems are designed to offer precise climate control, consuming less energy compared to traditional systems. They encompass sophisticated features such as adjustable thermostats, enabling operations customization to meet warehouse needs. Through such features, energy expenditure is controlled by scheduling specific temperature settings at different periods, thus reducing utility costs. These highly efficient HVAC systems often qualify for rebates or incentives from utility providers or government schemes. Despite a high initial cost, their long-term financial advantages validate the investment. It’s essential to account for your warehouse’s unique heating and cooling demands before transitioning to ensure optimal system selection. Factors such as warehouse size, insulation conditions, and local weather must be taken into account during the decision-making process.

Implement Temperature Zoning

Creating designated temperature sections within your storage facility is an effective strategy for managing climatic control more economically. This approach involves dividing your facility into several sections, each equipped with its own temperature regulations. By applying this strategy, you can tailor the temperature controls based on the specific requirements of each section, thereby optimizing energy consumption.

This method proves highly beneficial in large storage facilities where different sections may require varied temperature settings. For example, a section of your facility might store climate-sensitive commodities requiring a cooler atmosphere, while another section meant for packaging and dispatch might necessitate a slightly warmer environment for the comfort of the workforce. By delineating distinct zones, you can maintain the ideal temperature in each section, eliminating any energy wastage through unnecessary heating or cooling.

Employ Natural Ventilation

Harnessing the power of nature can provide an effective, economical solution for warehouse temperature management. Implementing a natural ventilation strategy involves creating strategic openings, such as windows, vents, and skylights, throughout your warehouse. These allow the free flow of air, resulting in a cooler, more balanced internal temperature.

Utilizing natural ventilation can significantly lessen the reliance on energy-consuming HVAC systems. In many cases, the natural movement of air, assisted by the temperature difference between the inside and outside of the warehouse, can provide enough circulation to maintain a comfortable temperature. In the cooler months, this approach can be combined with other heating methods to maintain warmth without over-relying on energy-intensive systems.

Natural ventilation can also contribute to the quality of the warehouse environment. Constant fresh air flow can decrease the concentration of airborne pollutants and enhance the overall air quality. This provides a healthier workspace, potentially contributing to improved staff productivity and job satisfaction.

Contact Refresh Fans

Partnering with industry experts can be the key to unlocking optimal warehouse temperature control and energy efficiency. Companies like Refresh Fans stand out in this area. Our team of seasoned professionals is equipped with the necessary knowledge and tools to assess your unique needs, offering custom-fit solutions to enhance your warehouse’s temperature regulation. Make the strategic decision to reach out to us today and invest in a solution that pays dividends in the long run.